EUROCC Case Study: Simulation-Optimization of a Patented Design with Parallel Computing on TRUBA cluster

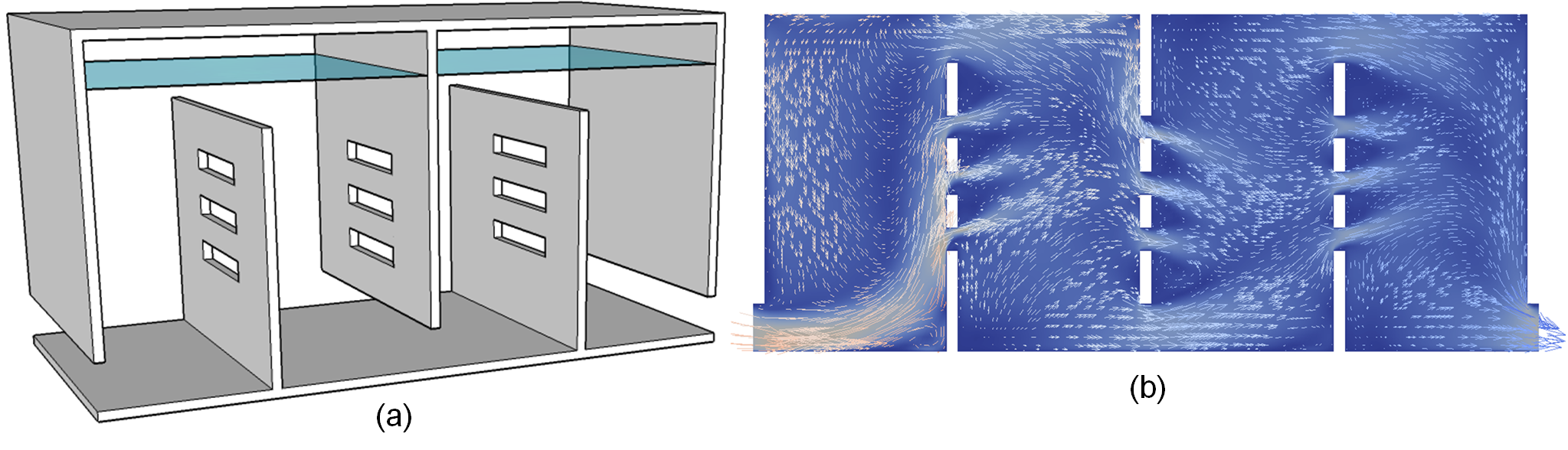

Treatment of surface waters in large cities has been emerged as a critical point of interest for governments in recent years with increasing clean water demand and development of energy intensive water treatment technologies such as ozone and ultraviolet. Raw water is mixed with the disinfectant in a multi-chambered contact tank at the last stage of the treatment procedure to remove viruses and pathogens from the water. Although an efficient contact system is required for the effective disinfection of water with less disinfectant and energy usage, conventional mixing systems suffer from low mixing and high energy requirements due to the recirculation effects and short-circuiting occurred inside the chambers. To this end, DSTECH invented a slot-baffle design, in which slots are created at specific locations of the baffle in order to to improve mixing efficiency of the system by increasing interaction between two neighbouring chambers.

In this case study, the patented design is optimized using an augmented simulation-optimization framework developed by DSTECH team on TRUBA resources. Optimization of the slot-baffle design is performed in three stages:

Stage1: Slot size is optimized based on the variation of diagonal length (both y and z direction)

Stage2: Width and height of the slots are optimized separately.

Stage3: Locations of the slots are optimized for the dimensions obtained from Stage 2.

Developers

Prof. Dr. Ender Demirel

Mustafa Kuzay

Licence

Copyright 2021 Design and Simulation Technologies Inc.

Distributed using the GNU General Public License (GPL), version 3; see the LICENSE file for details.